|

|

|

|

| Catphan 500/600 CT Phantoms. |

|  Comprehensive CT Performance Measurements

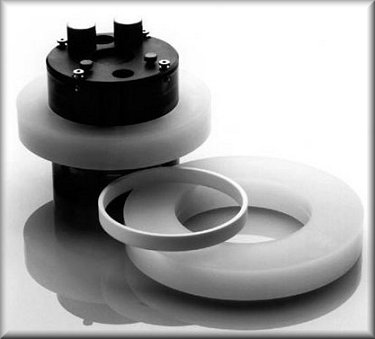

Comprehensive CT Performance MeasurementsCatphan® Phantoms are internationally recognized for measuring the MAXIMUM obtainable performance of axial, spiral and multislice CT scanners. The Phantom Laboratory and physicist, David Goodenough, Ph.D., have worked together to develop the Catphan® Phantoms. The new Catphan® designs are based on three decades of scientific research and direct field experience in the evaluation of medical imaging equipment. These phantoms are used to complete comprehensive performance evaluations of axial, spiral and multislice CT scanners and to implement quality assurance programs. The Catphan® Phantoms are constructed from modules that fit snugly into a durable 20cm housing. With the exception of the water tank module used in the Catphan® 424, all Catphan® modules are made from solid-cast materials. Solid-cast construction eliminates material absorption of water, freezing and leaks associated with water bath phantoms, as well as, problems related to varied water sources. |

| Tests - Summary |  |

|

Catphan® 700 (Stock CTP700) - Complete Catphan® including housing and case,

equipped with the following test

modules: CTP682 - Geometry sensitometry and point source module CTP714 - 30 line pair high resolution module CTP515 - Subslice and supra-slice low contrast CTP721 - Wave insert CTP723 - Bead blocks CTP712 - Uniformity section Catphan® 600 (Stock CTP600) - Complete Catphan® including housing and case, equipped with the following test modules: |

| CTP404 - Slice width, sensitometry and pixel size CTP591 - Bead Geometry module CTP528 - 21 line pair high reslution and point source CTP515 - Subslice and supra-slice low contrast CTP486 - Solid image uniformity module Catphan® 500 (Stock CTP500) - Complete Catphan including housing and case, equipped with the following test modules: CTP401 - Slice width, sensitometry and pixel size CTP528 - 21 line pair high resolution and point source CTP515 - Subslice and supra-slice low contrast CTP486 - Solid image uniformity module |  |

|

| AutoQALite Software for use with the CatPhan CT Phantoms. |

An updated Windows program to the original PC/AutoQA for CT. This update provides expanded image processing capacity for

up to 96 images in a data set with a comprehensive trend analysis feature.

An updated Windows program to the original PC/AutoQA for CT. This update provides expanded image processing capacity for

up to 96 images in a data set with a comprehensive trend analysis feature.PROCESSING FEATURES CT AutoQA Lite™ can be configured with various vendor phantoms including ACR and all Catphan® models. CT AutoQA Lite™ is DICOM3.0 compatible, a DICOM Storage Provider (SCP) Application license is provided. CT AutoQA Lite™ provides the same analysis function as the original PC/AutoQA (DOS) version. |

|

|

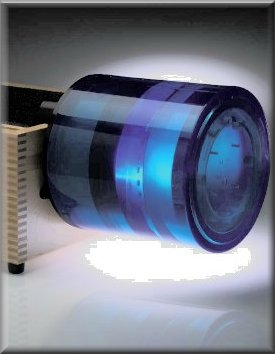

| Catphan®

section CTP401 and CTP404.

|

|

|  |

|

|  | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| range determined by + 2 times the central noise or + 10H, whichever is smaller.

NEW FEATURES The Catphan 600 bead module consists of 2 different sets of angled ramps containing small tungsten beads in a 40mm thick section. The first set consists of 2 pairs in opposing directions, one pair oriented horizontally and the other pair oriented vertically. This uses 0.34mm diameter beads with an "effective" separation of 1.0mm. The second set contains only a single pair of smaller beads (0.17mm diameter) oriented vertically with an "effective" separation of only 0.25mm. This type of test object allows the user to make a visual estimate of the actual slice thickness by counting the |

|

|

| individual beads in the image and multiplying by the known separation. The beads at both ends of the set that are

visualized in the image may be a much less intensity than the more centrally located beads in which case they might be

only counted as ½. The AutoQA Lite program basically performs this visual assessment. However, since the data is

processed quantitatively, it is possible to use some weighting scheme for the terminal beads to provide a more objective

weighting factor. In addition, since the ramps are always used as opposing sets, it is also possible to perform

additional calculations that would affect the quality of this test and the reliability and accuracy of the results. This

includes: the axial offset of the center of this module with respect to the slice location and angular tilt of the

phantom vertically and horizontally. Lastly, this module contains an off-centered wire as an impulse response source

through the entire 40mm module thickness allowing for MTF measurements for each slice. RESULT FEATURES CT AutoQA Lite™ provides two database options for storage of test results. "Monitor Database", is the first |

| database option designated for constancy/monitoring and is linked to the Trend Analysis function. The 'Service Database'

is the second data base option and is designed for more extensive service and/or acceptance testing data sets. If

neither of these two options is appropriate, the user can select the option to not store results but only view results.

The basic display of results is provided as a scrolling window, with a print "Test Results" function button.

The Trend Analysis feature is available for Noise/Mean CT number, slice width, spatial resolution (MTF), and CT

linearity measurements. The Trend Analysis function is linked to the monitor database files and follows guidelines for

CT constancy testing established by the International Electrotechnical Commission (IEC) 1223-2-6 (Constancy tests -

X-ray equipment for computed tomography, First Edition 1994-04). MINIMUM SYSTEM REQUIREMENTS Minimum Requirements for Windows XP, CD drive |

|

|